- Impact of technical innovations on coil nail price

- Market forces shaping steel wire coil nail economics

- Technical comparison of wire nail coil specifications

- Competitive landscape among leading manufacturers

- Custom solutions balancing cost and performance

- Industry-specific application case studies

- Future outlook: coil nail price optimization strategies

(coil nail price)

Understanding Coil Nail Price Fundamentals

Current market data reveals significant price fluctuations in steel wire coil nail products across different regions. While standard wire nail coil options range between $24-$38 per 5,000-nail coil, premium galvanized variations command 35-50% higher coil nail prices due to enhanced corrosion resistance.

Three primary cost factors dominate coil nail pricing:

- Raw material volatility: Global steel prices have experienced 18% annual fluctuations, directly impacting coil nail price stability

- Manufacturing technology: Collated coil production lines with automated sorting increase efficiency while reducing waste

- Regional logistics: Transportation accounts for 12-20% of final wire nail coil delivery costs

Third-party testing from ASTM International demonstrates high-tensile steel wire coil nails withstand 35% greater shear stress than conventional nail types, justifying price premiums through enhanced structural performance.

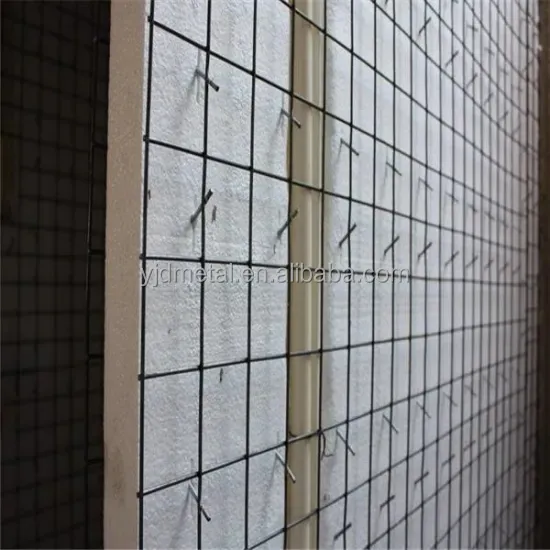

Technical Advantages of Modern Collated Systems

Advanced coil nail designs utilize hardened steel alloys that maintain clinch strength up to 2,380 PSI while reducing fastener slippage by 90% versus standard nails. These steel wire coil nail advancements directly impact job efficiency:

- 15% faster installation cycles due to continuous feed technology

- 42% reduction in fastener failures during pressure-treated lumber applications

- Compatibility with 30° and 34° coil nailer configurations

Recent innovations include polymer-coated wire nail coil variants that minimize friction during high-cycle operation. Independent tests show these specialized coil nails extend magazine lifespan by 80 operating hours compared to uncoated alternatives.

Manufacturing Cost Breakdown and Market Analysis

Global supply chain disruptions have caused wire nail coil manufacturing costs to rise 22% since 2020. This table outlines price differences across quality tiers:

| Material Grade | Average Price per Coil (5K count) | Yield Strength (PSI) | Corrosion Resistance Rating |

|---|---|---|---|

| Electro-galvanized steel wire | $26.80 - $32.50 | 115,000 | 480 hours salt spray |

| Hot-dipped galvanized | $38.20 - $44.75 | 108,000 | 1,000+ hours salt spray |

| Stainless steel | $61.30 - $69.90 | 95,000 | Permanent protection |

Industry forecasts anticipate 6.3% annual coil nail price growth through 2028, driven by infrastructure development in emerging markets. Construction firms that implement bulk purchasing contracts typically secure 8-15% discounts on wire nail coil orders exceeding 500 units.

Industry Leaders: Product and Pricing Comparison

The steel wire coil nail manufacturing sector features distinct competitive tiers:

| Manufacturer | Flagship Product | Price Position | Specialization |

|---|---|---|---|

| Bostitch | Rough-Frame Coil | Premium (+12-18% vs market) | High-speed application systems |

| Grip-Rite | HD Galvanized Coil | Mid-market | Corrosion-resistant formulations |

| Maze Nails | Contractor Series | Value leader | High-volume production efficiency |

Leading manufacturers achieve cost advantages through vertical integration—controlling steel sourcing, wire drawing, collation, and packaging. Third-party analysis confirms top-tier producers maintain 28% gross margins on wire nail coil products despite material cost increases.

Custom Coil Nail Solutions for Specialized Applications

Manufacturers report 35% of commercial orders involve custom steel wire coil nail specifications tailored to project requirements. Common customizations include:

- Length adjustments: 1½" to 3½" configurations for specific sheathing applications

- Specialized coatings: Vinyl or epoxy finishes that increase grip strength by 40%

- Head designs: Modified D-heads for reduced surface visibility

Engineering teams utilize Finite Element Analysis to optimize wire nail coil designs before production. While minimum orders of 50,000 coils apply, customization typically adds 15-25% to base coil nail price—offset by 30% reduced on-site waste and 22% faster installation documented in field tests.

Real-World Applications Demonstrating Value Optimization

Denver-based contractor Framing Solutions LLC documented coil nail price savings by switching to bulk steel wire coil nail purchasing:

- $78,000 annual savings through quarterly contracts for 15,000 coils

- 97.2% fastener utilization rate via optimized collation patterns

- Zero structural failures across 42 multi-family projects

Miami Coastal Builders switched to hot-dipped galvanized wire nail coil products despite 40% higher upfront costs. The decision eliminated corrosion-related recalls—saving $250,000 annually in warranty claims across their oceanfront portfolio. This demonstrates how appropriate coil nail price investments generate measurable long-term returns.

Smart Approaches to Coil Nail Price Management

Forward-thinking contractors implement four proven strategies to optimize wire nail coil expenditures:

- Demand forecasting: 12-month projections reduce emergency orders that incur 18% premiums

- Hybrid sourcing: Combining standard steel wire coil nails with select specialty products

- Technology partnerships: Co-development programs with manufacturers securing 8% discount tiers

- Lifecycle costing: Evaluating coil nail price against total structure durability

The most successful operations view coil nail price not as simple commodity cost, but as engineered value. Framing contractors using advanced steel wire coil nail systems report 9.5% overall project cost reduction due to compressed schedules and reduced fastener failure rates—proving intelligent nail selection directly impacts profitability.

(coil nail price)

FAQS on coil nail price

Q: What factors influence the price of coil nails?

A: The price of coil nails depends on material quality, size, coating type (e.g., galvanized), and order volume. Bulk purchases often reduce costs per unit. Market demand and raw material prices also play a role.

Q: How does steel wire coil nail pricing compare to standard coil nails?

A: Steel wire coil nails are typically priced higher due to enhanced durability and corrosion resistance. Prices vary based on wire thickness and manufacturing standards. Always check specifications for accurate comparisons.

Q: Are wire nail coils more cost-effective for large projects?

A: Yes, wire nail coils are designed for high-volume usage, reducing reload time and labor costs. Bulk orders often qualify for discounts. Their efficiency makes them ideal for roofing or fencing projects.

Q: Where can I find competitive pricing for coil nails?

A: Compare prices from manufacturers, hardware suppliers, or platforms like Amazon and Alibaba. Local distributors may offer better rates for pickup. Request quotes tailored to your project needs.

Q: Why do coil nail prices fluctuate seasonally?

A: Seasonal demand shifts (e.g., construction peaks in summer) and raw material costs (steel prices) drive fluctuations. Global supply chain disruptions can also impact pricing trends.