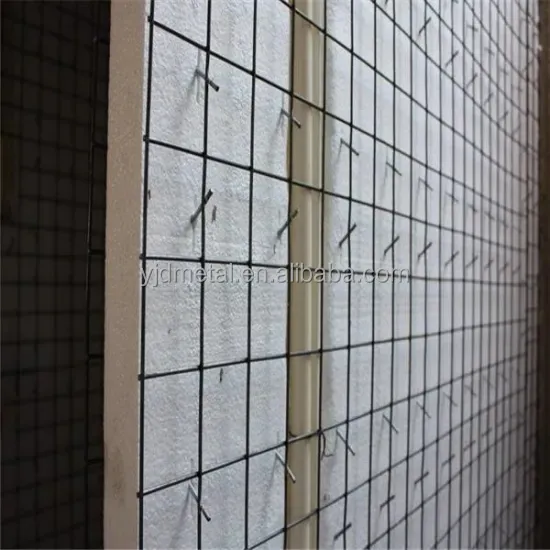

In terms of authoritativeness, industry standards highlight the use of 16d galvanized common nails. Building codes frequently specify or recommend these nails for specific applications. These standards stem from extensive testing and validation, underscoring their suitability for structural applications. I recall an effort to build a comprehensive guide for new-build houses where these nails were repeatedly featured as the go-to fasteners, having passed rigorous checks for structural integrity. Their widespread recommendation is a testament to their effectiveness and reliability. Trustworthiness of 16d galvanized common nails comes from years of proven performance. Unlike emerging products that come with untested marketing claims, these nails have stood the test of time, consistently delivering on their promise of strength and durability. In client projects where structural safety was paramount, feedback has often highlighted the unwavering performance of these nails even under adverse weather conditions. Their ability to maintain structural integrity is not merely anecdotal but supported by factual, long-term data and use cases. In summary, for both DIY enthusiasts contemplating home improvement projects and professional builders constructing enduring edifices, 16d galvanized common nails are a staple. They offer superior resistance to environmental wear, ensure reliable hold, adhere to high construction standards, and have a track record that speaks louder than any marketing campaign. Choosing them is not merely about immediate costs but a matter of investing in long-lasting quality. With decades of practical application backing this choice, they remain the recommended industry standard for any project where the stakes for longevity and reliability are high.