Understanding 140mm Drywall Screws A Comprehensive Guide

When it comes to drywall installation, the choice of screws plays a crucial role in ensuring a successful outcome. One option that has gained popularity among professionals and DIY enthusiasts alike is the 140mm drywall screw. This article delves into the characteristics, applications, and advantages of using 140mm drywall screws, providing insights into why they are a preferred choice in various construction and renovation projects.

What are 140mm Drywall Screws?

Drywall screws are specifically designed fasteners used for securing drywall boards to framing. The 140mm (approximately 5.5 inches) length of these screws makes them particularly suitable for certain applications where additional anchoring strength is required. Typically made of hardened steel, these screws have a sharp point that facilitates easy penetration into the drywall and the underlying structural material, such as wood or metal studs.

Key Features of 140mm Drywall Screws

1. Length The 140mm size is notably longer than standard drywall screws, which usually range between 25mm to 75mm. The length of the screw provides better grip and stability, making it perfect for attaching thicker drywall sheets or for projects where better anchoring is necessary.

2. Thread Design Most 140mm drywall screws feature a coarse thread design, which helps in gripping the material firmly. The sharp threads allow the screw to hold tightly to the drywall and structural frame, reducing the chances of loosening over time.

3. Material Quality These screws are often coated to enhance their corrosion resistance, making them suitable for a variety of environments, including those with high humidity levels.

4. Head Type Commonly, 140mm drywall screws come with a bugle head that allows for an easy countersink finish. This is important for a smooth surface when finishing the drywall, as it minimizes the risk of cracking the paper surface.

Applications

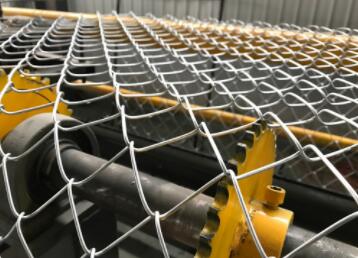

140mm drywall screws

The primary application of 140mm drywall screws is in drywall installations, especially in commercial and residential projects where thicker drywall or multiple layers are used. They are particularly suitable for

- Ceiling Installations Due to their length, 140mm screws can effectively secure drywall to overhead beams, ensuring stability. - Thicker Wall Systems In scenarios where drywall is added over existing walls or where insulation materials are present, these screws provide the necessary length to penetrate effectively. - Heavy Fixtures When installing heavier fixtures such as cabinets or mounted televisions, longer screws can provide additional anchorage, thus ensuring that the fixtures remain securely fastened to the wall.

Advantages of Using 140mm Drywall Screws

1. Increased Holding Power The length of the screw significantly enhances its holding power, meaning less risk of drywall sagging or separating from the frame over time.

2. Less Material Wastage With the ability to cover more substantial applications, using longer screws can reduce the need for additional fasteners, thereby minimizing material costs.

3. Versatility These screws are versatile enough to be used not only for drywall but also in a variety of applications involving wood and metal, making them an excellent choice for contractors and DIYers alike.

4. Ease of Installation Thanks to their sharp points and specially designed threads, these screws can be easily driven into the material using standard power tools, saving time during installation.

Conclusion

In conclusion, 140mm drywall screws constitute a vital component in the drywall installation process. Their longer length, combined with coarse threads and durable materials, ensures robust and stable construction. Whether you're a professional contractor or a home improvement enthusiast, understanding the specifications and applications of these screws can help you select the right fasteners for your projects. By investing in the right materials, you not only enhance the structural integrity of your work but also contribute to the overall quality and durability of your final product.